Magnaflux PeneCert™ Testing Service helps our customers stay in compliance with relevant specifications and save money. When samples are analyzed, certificates are generated, and the data is stored in the Magnaflux PeneCert™ Database. This data can be used to help our customers when they are faced with specification compliance. Here is a recent case study from one customer.

A PeneCert™ customer recently contacted us about the viscosity of their Zyglo ZL-60D. The in-use viscosity was slowly increasing each month. They were concerned that the viscosity would increase to the point that would cause the penetrant tank product to be out of conformance with their specification. The NDT team would then need to discard the Zyglo material in their tank and replace it with new Zyglo penetrant. The penetrant water content was less than 1%, which was below the 5% specification. This customer reached out to the Magnaflux team to understand why their viscosity was increasing each month.

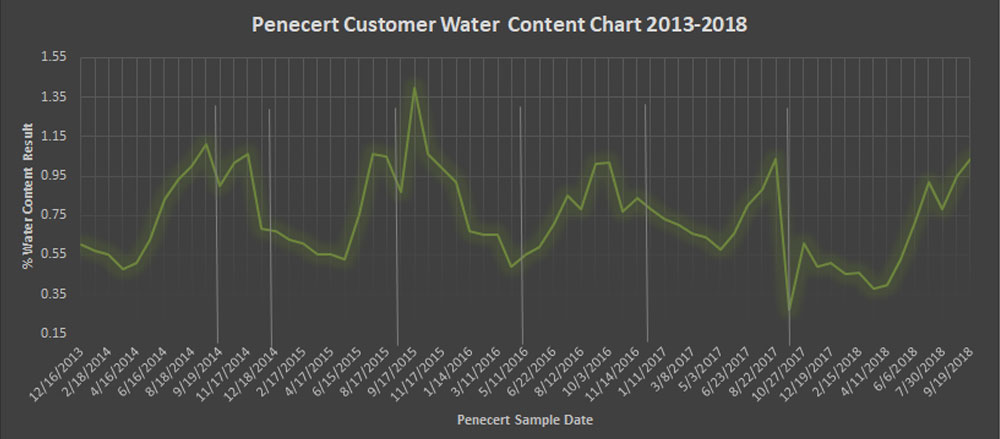

Fortunately, this PeneCert™ customer has been a customer for many years, so the Magnaflux Quality Team had access to regular test record dating back to 2013. The stored data was analyzed, and the team was able to see a direct correlation between water content and viscosity.

As the water content increased, so did the viscosity. The first graph below shows the PeneCert™ viscosity data from 2013 to 2018. The lines indicate when a new batch of Penetrant was added to the tank. As you can see, the batch viscosity steadily increased over time.

The below graph shows the water content in green and viscosity in gray. Even a slight increase in water content effects the viscosity of the penetrant. When the customer understood how the water content effects the viscosity, they were able to modify their process to reduce the amount of water being introduced into their tanks.

This is an example of the type of application support that the Magnaflux Quality Team can offer to our PeneCert™ customers. The Quality Team not only offer test results but can add insights into the process through data analysis, so customers can adjust keep costs down and stay in compliance.