Magnaflux offers custom Magnetic Particle Equipment to address many of our customer’s unique needs. In the past, we have tackled projects large and small that got us to put our creative hats on, and solve our customer’s pain points in new ways. Below are two examples that highlight our commitment to tackling the biggest MPI challenges.

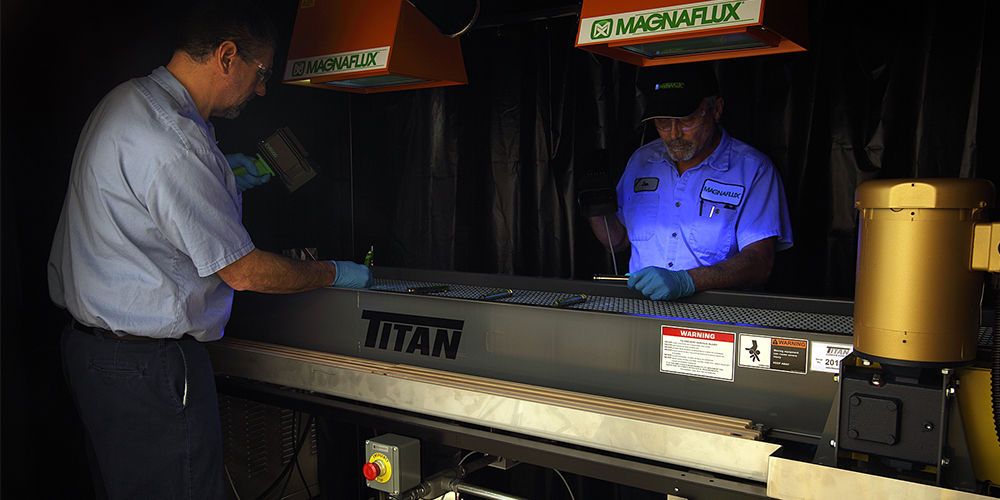

MD Unit with XG-Series Conveyor Inspection Booth

The above unit was made for an automotive customer who wanted to increase throughput. One option to do this is with an XG-Series conveyor leading from the MD-Series testing area to a separate inspection hood. Read more >>>

This customer was inspecting only a portion of their parts at the time, but was looking to go to 100% inspection. Thus, their biggest need was to increase throughput. They also had variable production rates, meaning that at any time they would have 1-4 inspectors on the job.

To address their throughput concerns, Magnaflux combined a multidirectional MD unit capable of magnetizing the entire part in 1 shot, with an XG series conveyor for faster part transport. The frame was customized to easily accommodate the conveyor while keeping parts at working height. The head and tail stocks were positioned so that the conveyor could easily slide in. An automatic demagnetizer was added at the end of the conveyor for easy removal and less part handling.

All in all, the customer now had a high-speed inspection solution that could accommodate 100% of their parts, with the flexibility to bring in extra operators when needed.

Engine Block Unit

Custom units come in many shapes and sizes. This mag particle unit is made with three coils to fit an 500 lb engine block to be tested. Our Magnetic Coils range from 12-25 inches, and are optional add-ons for A-Series, D-Series, or MD-Series magnetic benches.

This customer needed a way to inspect large, 500lb, engine blocks, while still being fast enough to match the rest of their production process. To meet their requirements, Magnaflux would have to find a way to magnetize the whole block in one shot, and demagnetize it quickly down the line.

To address this problem, Magnaflux created a machine with three auxiliary coils that fit around the engine block, which magnetized thee entire block in one shot. This configuration also reduced their demagnetization time by 50%, further speeding up the inspection. The machine is capable of inspecting parts up to 60 inches long and weigh up to 1000 pounds, and comes with automatic part rotation that allows for easier part handling.

We always love a challenge, especially our Engineering team! Call us if you want to brainstorm ideas together, or get a jump start by filling out our Magnetic Particle Inspection Equipment Checklist.

Published March 27, 2018